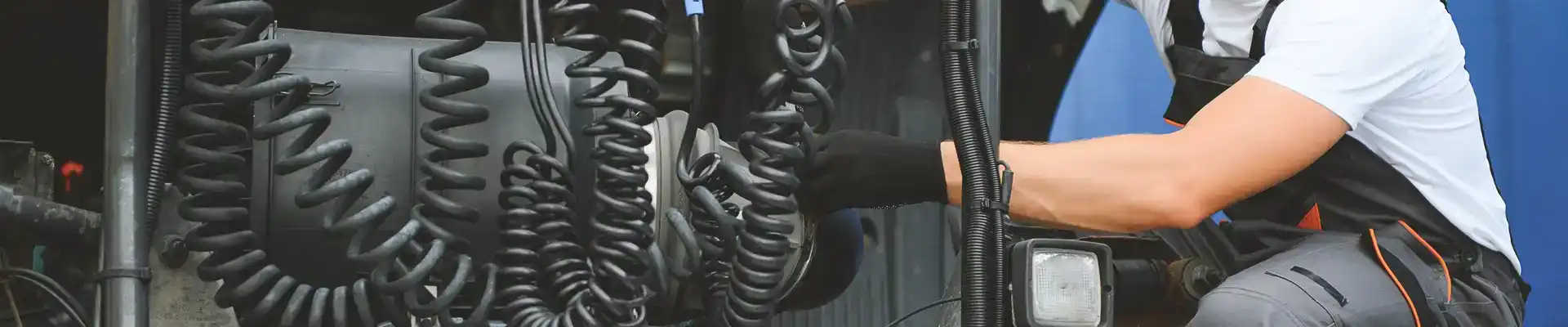

When a hydraulic hose fails, it doesn’t just halt your equipment; it halts your day. At Axle Spindle Repair, we understand the urgency. That’s why we offer expert mobile hydraulic hose repair services throughout the Greater Toronto Area.

Hydraulic hose repair in trucks involves diagnosing leaks or failures in systems such as dump beds, lifts, steering, and hydraulic attachments. Our technicians are equipped to handle it on-site, minimizing downtime and getting you and your equipment back to work.

From hydraulic hose replacement to emergency fixes, we ensure every repair meets OEM standards. If you’ve been searching for “hydraulic hose repair near me” or “mobile hydraulic hose repair shop in Toronto,” look no further. Backed by 20+ years of hands-on expertise, Axle Spindle Repair is your trusted local partner, ensuring your hydraulic systems are repaired quickly and your operations stay moving.

Truck Hydraulic Hose Repair Services

››› Diagnosis of Hose Failures

We quickly diagnose hydraulic hose problems by finding leaks, internal ruptures and surface wear. Early detection saves you money, prevents major system failures and keeps your equipment running at full pressure and performance.

››› Removal and Replacement

Our hydraulic hose technicians safely remove damaged or leaking hoses and replace them with high quality assemblies built to handle your machine’s pressure, temperature and environmental requirements. We match every replacement to your original equipment specifications.

››› Custom Hose Assembly

Need a custom solution? We build pressure-resistant hose kits and hydraulic hose assemblies to your exact specs, length, diameter, fittings, and pressure rating, using high-quality liners, reinforcement, and protective layers for any truck application.

››› Pressure Testing and Inspection

Every hydraulic hose repair or replacement is pressure-tested and inspected to ensure it can handle the required load. For reliable service, from mobile hydraulic hose repair in Toronto to fast hose replacement, we deliver safe and trusted results.

››› Preventive Maintenance

We offer preventative maintenance programs that include visual checks for leaks and abrasion, torquing fittings, pressure testing, fluid analysis, and scheduled hose replacement per OEM standards. Our hydraulic hose repair service supports fleets in the GTA that need mobile hydraulic hose repair.

Common Signs You Need Hydraulic Hose Repair

Visible Fluid Leaks

If you see drips, or oil puddles under your equipment, it’s a big sign of a hose failure. Hydraulic hoses should contain high pressure fluid without any leaking. A visible leak means cracks, punctures, or compromised hose integrity.

Loss of System Pressure

A sudden loss of hydraulic pressure results in weak operations or sluggish system performance. This can be caused by pinhole leaks, internal hose ruptures, or fittings that have become loose over time. If your equipment isn’t running at full power, a damaged hydraulic hose might be the reason.

Hose Deterioration

Old truck hoses show signs of wear and tear like cracking, blistering, fraying or rotting. Even small surface damage can become a big rupture when pressurized. Replacing deteriorated hoses early prevents unexpected, expensive emergency hose replacements.

Unusual Noises or Movements

If you hear hissing, see strange vibrations or jerking movements, you might have a hydraulic hose leak or break. These sounds mean high pressure fluid is escaping and the hose can fail at any moment.

Failed Pressure Checks

Failing hydraulic pressure tests often reveal hidden damage to hoses. Stretching or weakening hoses can reduce system pressure significantly. Address these issues immediately with professional hydraulic hose repair or mobile hydraulic hose repair in the GTA to prevent downtime.

Loose or Leaking Connections

Sometimes the issue isn’t the hose but the corroded or loose fittings that release fluid under pressure. Regular maintenance catches these connection failures early. If a fitting blows, contact our emergency hydraulic repair shop to prevent bigger system damage.

Hydraulic Hose Maintenance Tips For Trucks

Inspect Regularly

Check hoses daily for wear and weekly for deeper issues. Look for cracks, bulges, leaks, chafing, or stiff spots—especially near fittings. Catching damage early helps avoid costly hydraulic hose repairs or system failures down the line.

Protect Against Heat and Friction

Use heat shields or wraps near hot components, and add abrasion sleeves where hoses rub or flex. Keep routing smooth—no sharp bends or tight loops. Poor setup leads to kinks, leaks, and reduced hose life.

Use High-Quality Parts

Cheap bushings wear out fast. Use premium heavy-duty king pin bushings and OEM rated parts.

Maintain Connections and Seals

Loose or corroded fittings can cause pressure loss and leaks. Check torque specs, inspect O-rings and threads, and keep all couplings clean. Tight, secure fittings mean fewer truck breakdowns.

Monitor Pressure and Fluids

Watch for pressure drops and check your hydraulic fluid regularly. Dirty or degraded fluid damages hoses quickly. To prevent heavy-duty truck hydraulic hoses from clogging, keep the fluid clean and within spec to reduce wear.

Replace Hoses Before They Fail

Replace hoses every 5 years or every 100,000–160,000 km, but always follow your truck’s OEM schedule. For older trucks, replace hoses proactively as a set and inspect all hydraulic, coolant, fuel, and vacuum lines during routine service to prevent failures and downtime.